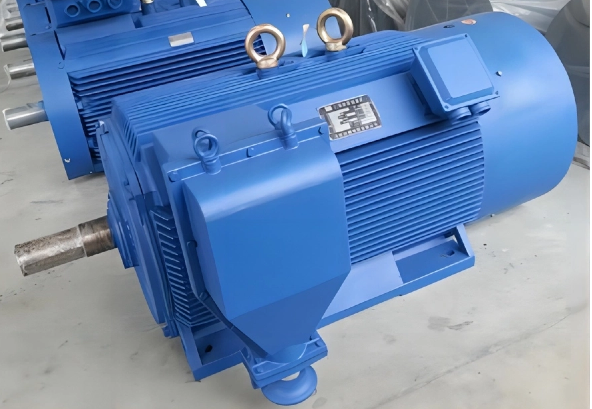

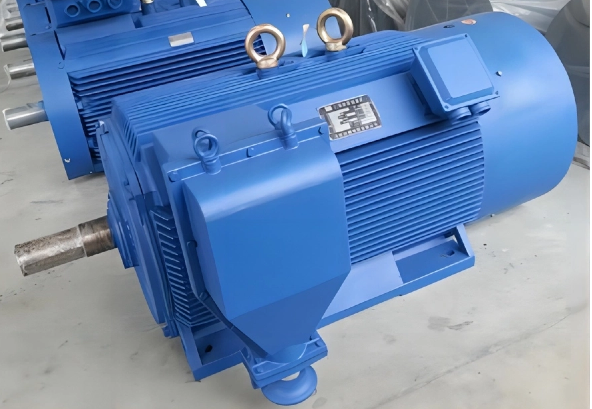

As one of the most widely used types of electric motors in the world, the asynchronous motor—also known as the induction motor—plays an irreplaceable role in industrial drives. From manufacturing plants to conveyor systems, from pumps and fans to compressors, asynchronous motors have become the backbone of modern industrial automation. Their robustness, cost-effectiveness, and adaptability to various load conditions make them the preferred choice for countless applications.

In industrial production, reliable and efficient motor systems are essential to ensure smooth operations, reduce downtime, and optimize energy consumption. Asynchronous motors excel in this regard, providing stable torque, long service life, and relatively simple maintenance compared to other motor types. This article explores the working principles, structural components, starting methods, and performance evaluation metrics of asynchronous motors, helping you better understand why they remain the cornerstone of industrial drive systems.

Basic Working Principle

Electromagnetic Induction and the Rotating Magnetic Field

The asynchronous motor operates on the principle of electromagnetic induction, as first described by Michael Faraday and later applied in practical motor design by Nikola Tesla. In a three-phase asynchronous motor, the stator windings are connected to a three-phase AC power supply, which creates a rotating magnetic field inside the stator.

When the rotor is placed within this rotating magnetic field, the relative motion between the field and the rotor conductors induces an electromotive force (EMF) according to Faraday’s law of induction. This induced EMF generates a current in the rotor, which in turn interacts with the stator’s magnetic field to produce torque. The motor thus begins to rotate, converting electrical energy into mechanical energy.

The Concept of Slip and Its Influencing Factors

One of the defining characteristics of an asynchronous motor is the presence of "slip"—the difference between the synchronous speed (the speed of the rotating magnetic field) and the actual rotor speed. Slip is necessary for electromagnetic induction to occur; without it, no relative motion would exist, and no current would be induced in the rotor.

Slip depends on various factors, including load conditions, rotor resistance, and supply frequency. Under light loads, slip is minimal, while under heavy loads, slip increases. Typical slip values for standard industrial motors range from 0.5% to 6%, depending on the design and application.

Main Structural Components

Stator Structure and Winding Types

The stator is the stationary part of the asynchronous motor and serves as the source of the rotating magnetic field. It consists of a laminated steel core with slots that house the copper or aluminum windings. These windings can be distributed or concentrated, with the choice depending on performance requirements, cost, and manufacturing processes.

The stator core laminations are insulated from each other to reduce eddy current losses, which improves efficiency. High-quality insulation materials and precise winding techniques are critical to ensuring the motor’s long-term reliability.

Rotor Types (Squirrel-Cage and Wound-Rotor)

The rotor is the rotating component of the motor, located inside the stator. There are two main types of rotors:

Squirrel-Cage Rotor – This is the most common rotor design, consisting of aluminum or copper bars short-circuited at both ends by conductive end rings. It is simple, robust, and requires little maintenance.

Wound-Rotor (Slip Ring) Rotor – This design uses three-phase windings connected to slip rings, allowing external resistors to be inserted into the rotor circuit during startup. This offers higher starting torque and more flexible speed control but requires more maintenance.

Bearings and Cooling Systems

Bearings support the rotor shaft, ensuring smooth rotation and alignment. Depending on the application, motors may use rolling-element bearings or sleeve bearings. Proper lubrication and sealing are essential to prolong bearing life.

Cooling is equally important, as motors generate heat during operation. Common cooling methods include open drip-proof (ODP), totally enclosed fan-cooled (TEFC), and water-cooled designs. Cooling ensures the motor operates within safe temperature limits, preventing insulation degradation and extending service life.

Starting Methods and Control Technologies

Direct-On-Line (DOL) Starting

The simplest and most straightforward starting method for asynchronous motors is the direct-on-line (DOL) start. In this approach, the motor is connected directly to the full supply voltage, allowing it to develop its maximum starting torque immediately. While this provides a quick and reliable startup, the major drawback is the very high inrush current, often reaching 6 to 8 times the motor’s rated full-load current. This sudden surge of current can cause voltage dips in the power network, potentially affecting other equipment. Additionally, the mechanical system experiences significant stress due to the rapid acceleration, which may lead to premature wear of components such as couplings, belts, and gears. Despite these issues, DOL starting remains widely used in applications where the power system can handle the surge and where the mechanical system is robust enough to tolerate the stress.

Star-Delta Reduced-Voltage Starting

To mitigate the high starting current associated with DOL starting, the star-delta (Y-Δ) reduced-voltage starting method is commonly employed, especially in medium-power asynchronous motors. Initially, the stator windings are connected in a star configuration, which effectively reduces the voltage applied to each winding to about 58% of the line voltage. This reduction in voltage lowers the starting current to roughly one-third of the DOL starting current, decreasing the electrical and mechanical stress during motor startup. Once the motor reaches approximately 70-80% of its rated speed, the connection switches to delta, applying full line voltage for normal operation. This method balances cost-effectiveness and performance, as it requires only a simple switching mechanism and does not demand sophisticated electronics. However, star-delta starting is less suitable for applications requiring high starting torque.

Soft Starters and Variable Frequency Drives (VFDs)

Modern motor control often employs electronic soft starters and variable frequency drives (VFDs). Soft starters gradually ramp up the voltage, reducing mechanical stress and electrical surges.

VFDs go further by controlling both voltage and frequency, allowing precise speed regulation, improved efficiency, and better process control. In energy-intensive industries, VFDs are essential for optimizing motor performance and reducing operating costs.

Performance Evaluation Metrics

Efficiency

Efficiency measures how effectively the motor converts electrical energy into mechanical energy. High-efficiency motors reduce power consumption, lower operating costs, and help meet energy regulations. Efficiency depends on factors such as design quality, winding resistance, and core losses.

Power Factor

The power factor represents the phase difference between voltage and current. In asynchronous motors, the power factor is usually less than 1 (lagging), meaning they draw more current than purely resistive loads. Improving the power factor through design enhancements or capacitor banks can reduce losses in the power system.

Overload Capacity

Overload capacity refers to the motor’s ability to handle loads exceeding its rated capacity for short periods without damage. This is critical in applications with fluctuating loads, such as crushers, conveyors, and compressors. Motors with high overload capacity offer better resilience and operational stability.

Conclusion

Asynchronous motors remain the workhorse of industrial drives due to their robustness, adaptability, and cost-effectiveness. Understanding their working principles, structural components, starting methods, and performance metrics enables engineers and operators to select the right motor for each application, ensuring reliable operation and energy efficiency.

For industries seeking high-quality asynchronous motors and advanced motor control solutions, Laeg Electric Technologies stands out as a trusted partner. With expertise in motor design, manufacturing, and customized engineering solutions, Laeg Electric Technologies delivers products that meet the highest standards of performance and durability.

To explore cutting-edge asynchronous motor technology and discover tailored solutions for your industrial needs, visit Laeg Electric Technologies today.