Are you considering the best motor for your needs? Understanding the differences between permanent magnet motors and induction motors is crucial.

This article explores their torque, losses, and materials. You'll learn how each motor type impacts performance and efficiency in modern applications.

Introduction

What are Permanent Magnet Motors?

Permanent magnet motors (PM motors) are a type of electric motor that uses permanent magnets to generate magnetic fields. Unlike traditional motors, they don’t rely on electromagnets. This design makes them efficient and compact.

Key Features:

● High Efficiency: PM motors convert electrical energy into mechanical energy with minimal losses.

● Compact Size: Their design allows for smaller and lighter motors.

● Low Maintenance: Fewer moving parts mean less wear and tear.

Importance in Modern Applications

In today's world, PM motors are found in various applications. They power everything from electric vehicles to household appliances. Their efficiency helps reduce energy consumption, making them essential for sustainable practices.

Overview of Induction Motors

Induction motors are another widely used type of electric motor. They operate on the principle of electromagnetic induction, where a rotating magnetic field induces current in the rotor. This design is robust and reliable.

Common Applications:

● Industrial Equipment: Used in pumps, fans, and conveyors.

● Home Appliances: Found in washers, dryers, and HVAC systems.

Purpose of the Article

This article aims to compare permanent magnet motors and induction motors. We will focus on three main aspects: torque, losses, and materials used in their construction.

By understanding these elements, you can make informed decisions about which motor type suits your needs best.

What You'll Learn:

● How torque differs between the two motor types.

● The various losses associated with each motor.

● The materials that impact performance and efficiency.

Understanding the Basics

How Do Electric Motors Work?

Electric motors convert electrical energy into mechanical energy. They achieve this through the interaction of magnetic fields and current-carrying conductors. When electricity flows through the motor, it creates a magnetic field that interacts with another magnetic field, causing motion.

Basic Principles of Electromagnetism

● Magnetic Fields: Created by electric currents.

● Lorentz Force: The force acting on a charged particle in a magnetic field.

● Induction: The process where a changing magnetic field generates electric current.

Role of Torque in Motor Operation

Torque is essential for motor performance. It represents the rotational force that the motor produces. The greater the torque, the more work the motor can do.

Torque Characteristics:

● Starting Torque: The torque when the motor begins to spin.

● Running Torque: The torque during normal operation.

● Peak Torque: Maximum torque available for short bursts.

Types of Electric Motors

There are several types of electric motors, each with unique characteristics. Here’s a brief overview:

Motor Type | Description | Common Uses |

AC Motors | Powered by alternating current. | Fans, pumps, and compressors. |

DC Motors | Powered by direct current. | Toys, electric vehicles, and tools. |

Stepper Motors | Moves in discrete steps. | 3D printers and CNC machines. |

Servo Motors | Provides precise control of angular position. | Robotics and automation. |

Specific Focus on Permanent Magnet and Induction Motors

Among these types, permanent magnet and induction motors are the most common in industrial applications.

● Permanent Magnet Motors: Utilize magnets for field generation, offering high efficiency and compact design. They excel in applications requiring high torque at low speeds, like electric vehicles.

● Induction Motors: Rely on electromagnetic induction to create motion. They are robust and widely used in various industries due to their reliability and lower cost.

By understanding these basics, we can better appreciate how each motor type functions and where they excel.

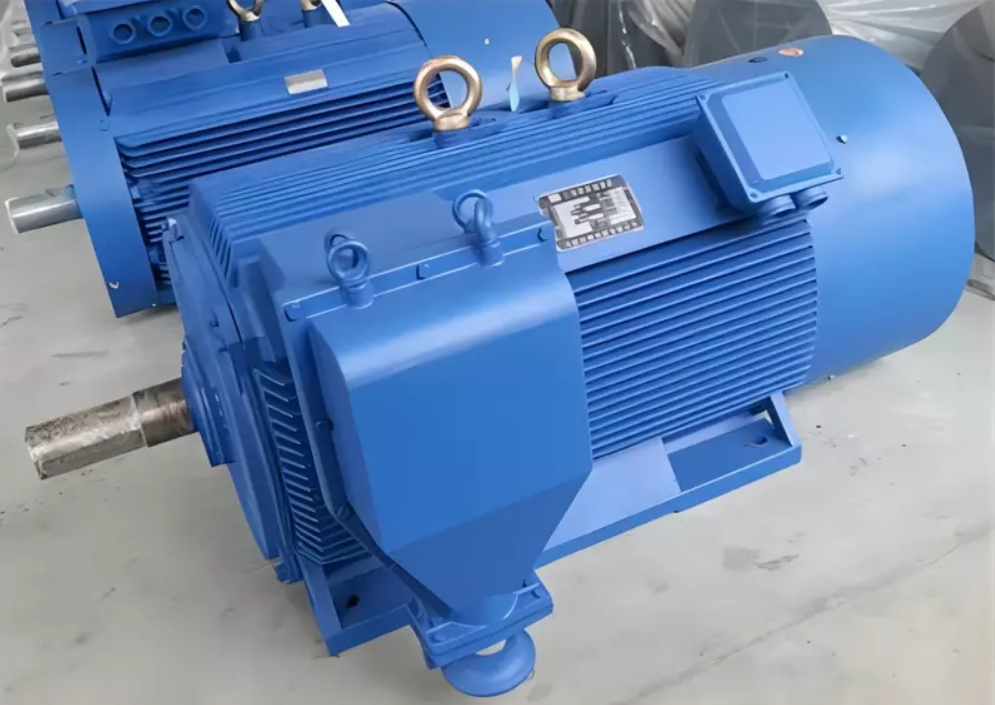

![permanent magnet motors permanent magnet motors]()

Torque Comparison

What is Torque in Electric Motors?

Torque is a measure of rotational force in electric motors. It plays a crucial role in determining how effectively a motor can perform its tasks.

Definition and Significance

● Torque: The force that causes an object to rotate around an axis.

● Significance: Higher torque means better performance, especially in applications requiring heavy lifting or fast acceleration.

How Torque Affects Motor Performance

Torque directly influences a motor's ability to start, accelerate, and maintain speed. Motors with higher torque can handle larger loads and operate more efficiently under varying conditions.

Torque Characteristics of Permanent Magnet Motors

Permanent magnet motors are known for their impressive torque characteristics.

High Starting Torque and Efficiency

● Starting Torque: These motors typically have high starting torque, allowing them to begin operation smoothly under heavy loads.

● Efficiency: They maintain efficiency across a wide range of speeds, making them ideal for applications like electric vehicles.

Torque-Speed Curve Analysis

The torque-speed curve illustrates how torque varies with speed.

● Key Points:

○ High torque at low speeds.

○ Gradual decrease in torque as speed increases.

Example from TYPKS Series

For instance, the TYPKS series of permanent magnet motors shows a torque range of 1.5 to 20 Nm for different power ratings. This flexibility makes them suitable for various applications.

Torque Characteristics of Induction Motors

Induction motors have distinct torque characteristics that set them apart.

Starting Torque vs. Running Torque

● Starting Torque: Generally lower than that of permanent magnet motors. This can lead to challenges in applications requiring immediate high torque.

● Running Torque: Once running, induction motors can maintain adequate torque levels, but they may not match the efficiency of permanent magnet motors.

Impact of Rotor Design on Torque Production

The rotor design significantly affects torque production in induction motors.

● Squirrel Cage Rotor: Commonly used, offering good performance and reliability.

● Wound Rotor: Provides better control over starting torque but is more complex.

Comparative Analysis

How Do the Torque Outputs Differ?

When comparing the two motor types, permanent magnet motors generally provide higher torque outputs at lower speeds.

Motor Type | Starting Torque | Running Torque | Efficiency |

Permanent Magnet | High | Consistent | High |

Induction | Moderate | Adequate | Moderate |

Advantages of Torque in Permanent Magnet Motors Over Induction Motors

● Higher Starting Torque: Ideal for applications needing quick acceleration.

● Better Efficiency: Less energy wasted, leading to lower operating costs.

● Compact Design: Smaller size allows for more flexible installation options.

By understanding these torque characteristics, we can see why permanent magnet motors are often preferred in many modern applications.

Losses in Electric Motors

What Are Motor Losses?

Motor losses refer to the energy that is lost during the operation of electric motors. Understanding these losses is crucial for optimizing performance and efficiency.

Definition and Types of Losses in Electric Motors

Motor losses can be categorized into several types:

● Copper Losses: Caused by the resistance in the windings.

● Iron Losses: Result from the magnetic properties of the core material.

● Stray Load Losses: Occur due to leakage and other inefficiencies.

Importance of Minimizing Losses for Efficiency

Minimizing losses is vital for maximizing motor efficiency. Lower losses mean more energy is converted into useful work, which translates to lower energy costs and improved performance.

Losses in Permanent Magnet Motors

Permanent magnet motors exhibit certain types of losses, similar to other motor types.

Types of Losses

1. Copper Losses: These occur in the windings and are proportional to the square of the current.

2. Iron Losses: Result from hysteresis and eddy currents in the magnetic core.

3. Stray Losses: Minor losses that can occur in various components.

How Design and Materials Affect Losses

The design and materials used in permanent magnet motors significantly influence losses. High-quality materials and optimized designs can reduce both copper and iron losses.

Comparison of Efficiency Levels

When comparing efficiency, consider the following:

● IE4 Motors: Ultra-high efficiency, with losses minimized through advanced design.

● IE3 Motors: High efficiency, but slightly higher losses compared to IE4.

Losses in Induction Motors

Induction motors also face various losses, which impact their efficiency.

Types of Losses

● Slip Losses: Occur due to the difference between synchronous speed and actual rotor speed.

● Rotor Losses: Result from the resistance in the rotor windings.

Comparison of Losses in Different Designs

Motor Design | Copper Losses | Iron Losses | Overall Losses |

Squirrel Cage | Moderate | Low | Moderate |

Wound Rotor | Higher | Moderate | Higher |

Comparative Analysis

Which Motor Type Has Lower Overall Losses?

Permanent magnet motors generally have lower overall losses compared to induction motors. This is due to their design and the absence of slip losses.

Implications of Losses on Operational Efficiency and Cost

Lower losses lead to better operational efficiency. This not only reduces energy costs but also extends the lifespan of the motor.

By understanding these aspects of losses in electric motors, one can make informed decisions about which type of motor to use for specific applications.

Materials Used in Electric Motors

What Materials Are Used in Permanent Magnet Motors?

Permanent magnet motors rely on specific materials to achieve their performance. The choice of materials directly impacts efficiency, torque, and overall functionality.

Types of Permanent Magnets

1. Neodymium Magnets: Known for their high strength, these magnets are widely used in various applications. They offer excellent performance but can be more expensive.

2. Ferrite Magnets: More cost-effective, ferrite magnets have lower magnetic strength. They are often used in applications where cost is a primary concern.

Importance of Material Selection for Performance

Selecting the right materials is crucial for optimizing motor performance. The magnetic properties, thermal stability, and mechanical strength of materials all influence how well a motor operates.

Insulation Classes and Their Impact on Durability

Insulation classes, such as F class, determine how well a motor can withstand heat. Higher insulation ratings mean better durability and longevity.

Insulation Class | Max Temp (°C) | Durability |

F Class | 155 | Good |

H Class | 180 | Excellent |

What Materials Are Used in Induction Motors?

Induction motors use different materials compared to permanent magnet motors. Understanding these materials helps in evaluating their efficiency and performance.

Rotor and Stator Materials

● Copper: Commonly used in windings for its excellent conductivity.

● Aluminum: Often used for rotor bars due to its lighter weight and cost-effectiveness.

● Silicon Steel: Used in stator cores, silicon steel enhances magnetic properties and reduces losses.

Impact of Material Properties on Motor Efficiency

The properties of these materials significantly affect efficiency. For instance, using high-quality silicon steel in the stator can minimize iron losses, leading to better overall performance.

Comparative Analysis

How Do Material Choices Affect Performance, Cost, and Longevity?

Material choices can greatly influence several factors:

● Performance: Stronger magnets or better conductors lead to higher efficiency.

● Cost: While neodymium offers better performance, it comes at a higher price.

● Longevity: Quality materials can enhance durability, reducing maintenance costs.

Environmental Considerations in Material Selection

When selecting materials, it's important to consider their environmental impact. Sustainable materials can reduce the carbon footprint of manufacturing processes.

By focusing on the right materials, we can enhance the performance and efficiency of both permanent magnet and induction motors, making them suitable for various applications.

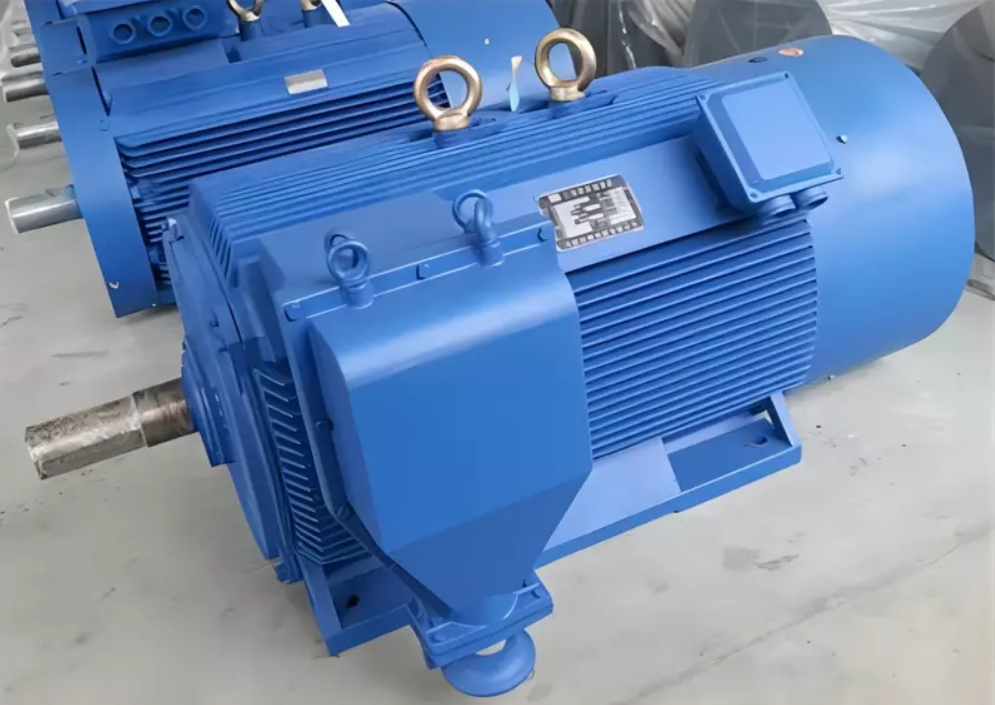

![permanent magnet motors permanent magnet motors]()

Applications and Suitability of Electric Motors

Where Are Permanent Magnet Motors Commonly Used?

Permanent magnet motors are becoming increasingly popular in various industries due to their efficiency and performance.

Examples of Applications

● Electric Vehicles (EVs): These motors provide high torque and efficiency, making them ideal for powering electric cars.

● Robotics: In robotics, precision and control are crucial. Permanent magnet motors excel in delivering accurate movements.

● HVAC Systems: Used in heating, ventilation, and air conditioning, these motors help improve energy efficiency.

Benefits of Using Permanent Magnet Motors in These Applications

The benefits of permanent magnet motors include:

● High Efficiency: They typically have lower energy losses, which is vital in applications requiring continuous operation.

● Compact Size: Their design allows for smaller and lighter systems, which is essential in space-constrained environments.

● Improved Torque Characteristics: They deliver high torque at low speeds, making them suitable for various applications.

Specific Advantages in High-Efficiency Scenarios

In high-efficiency scenarios, such as electric vehicles, the use of permanent magnet motors can significantly reduce energy consumption and extend battery life.

Where Are Induction Motors Commonly Used?

Induction motors are widely utilized in many industrial and commercial applications due to their robustness and reliability.

Examples of Applications

● Pumps: Commonly found in water supply and wastewater treatment, they provide consistent performance.

● Fans: Used in ventilation systems, induction motors ensure reliable airflow.

● Conveyor Systems: Induction motors power conveyor belts in manufacturing and logistics, offering durability and efficiency.

Benefits of Using Induction Motors in These Applications

Induction motors offer several advantages, including:

● Cost-Effectiveness: They are generally less expensive to manufacture and maintain.

● Simplicity: Their design is straightforward, leading to easier installation and operation.

● Versatility: Suitable for various applications, they can handle different load conditions effectively.

Suitability for Cost-Sensitive Applications

Induction motors are often the go-to choice for cost-sensitive applications where budget constraints are a priority.

Which Motor Is More Suitable for Specific Applications?

When selecting between permanent magnet and induction motors, consider the following factors:

Factors to Consider

● Power Requirements: Assess the power needs of your application. Permanent magnet motors excel in high-torque situations.

● Operational Conditions: Consider factors like temperature, load variability, and duty cycle.

Recommendations Based on Power Requirements and Operational Conditions

● For applications requiring high efficiency and compact design (like EVs), permanent magnet motors are ideal.

● For applications focused on cost and simplicity (like pumps or fans), induction motors may be more suitable.

By understanding the specific applications and suitability of each motor type, we can make informed decisions that enhance performance and efficiency.

Conclusion

In summary, both permanent magnet and induction motors have unique advantages.

Permanent magnet motors excel in torque and efficiency, making them ideal for electric vehicles and robotics.

Induction motors are cost-effective and reliable, suitable for pumps and fans.

When choosing a motor, consider efficiency, performance, and specific application needs.

Permanent magnet motors offer potential cost savings and longevity.

Explore permanent magnet motors for your applications and consult experts for tailored solutions.

FAQ

Q: What is the lifespan of permanent magnet motors compared to induction motors?

A: Permanent magnet motors typically have a longer lifespan due to lower wear and tear.

Q: Are permanent magnet motors more expensive than induction motors?

A: Yes, permanent magnet motors are generally more expensive due to their materials and manufacturing.

Q: Can permanent magnet motors operate in high-temperature environments?

A: They can, but high temperatures may affect performance and lifespan.

Q: What are the maintenance requirements for each motor type?

A: Permanent magnet motors require less maintenance, while induction motors may need regular checks.

Q: How do energy efficiency ratings compare between permanent magnet and induction motors?

A: Permanent magnet motors usually have higher energy efficiency ratings than induction motors.

Q: What are the noise levels associated with each motor type?

A: Permanent magnet motors tend to operate more quietly than induction motors.

Q: How do installation requirements differ between permanent magnet and induction motors?

A: Permanent magnet motors may require more precise installation, while induction motors are generally simpler to install.