With global industrial sectors facing increasing pressure to reduce energy consumption and carbon emissions, energy efficiency has become a critical focus. Electric motors, especially asynchronous motors (also known as induction motors), account for a substantial share of industrial electricity usage—often estimated at over 60% of total industrial power consumption. Despite their widespread use and proven reliability, traditional asynchronous motors may consume significant energy, especially when operating under suboptimal conditions such as frequent starts, idling, or running at fixed speeds regardless of load requirements.

Addressing the energy consumption challenges posed by asynchronous motors is essential for industries aiming to lower operating costs and meet stringent energy regulations. This article explores key strategies and technologies that enhance the energy efficiency of asynchronous motors, including optimized motor design, variable frequency drives (VFDs), soft-start techniques, and effective operational management. We also analyze the economic benefits of energy-saving retrofits and provide practical recommendations for industry professionals.

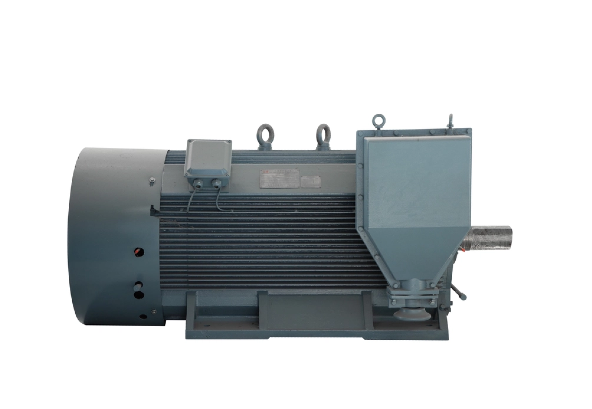

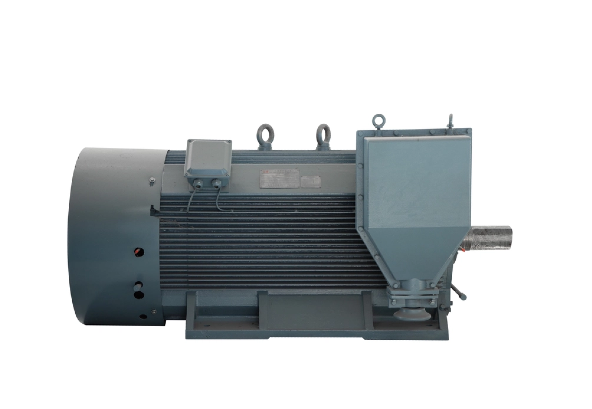

Design Optimization for High-Efficiency Motors

One of the fundamental approaches to reducing energy consumption is through motor design improvements. High-efficiency asynchronous motors incorporate several optimized features:

Improved Magnetic Materials: Using low-loss electrical steel laminations in the stator core significantly minimizes hysteresis and eddy current losses, which are major contributors to energy waste. This enhancement leads to improved overall motor efficiency and reduces operating costs over the motor’s lifespan.

Optimized Winding Design:Precision winding techniques combined with the use of high-conductivity copper materials reduce the electrical resistance in stator coils. This minimizes copper losses, enhances current flow, and contributes to better motor performance and energy savings during operation.

Enhanced Rotor Construction: Careful design and manufacturing of rotor bars and end rings help decrease rotor losses and slip. This reduction not only lowers heat generation within the motor but also improves energy conversion efficiency, leading to longer motor life and more reliable performance.

Better Thermal Management: Improved cooling systems, such as optimized fan designs or liquid cooling options, help maintain the motor at optimal operating temperatures. Effective thermal management prevents efficiency degradation caused by overheating and ensures consistent motor output under heavy load conditions.

These design improvements enable motors to achieve efficiency levels compliant with or exceeding standards such as IE3 or IE4, representing significant energy savings over standard motors. Replacing older motors with high-efficiency asynchronous motors is a common and effective energy conservation measure in many industries.

Energy Saving Principles of Variable Frequency Drives (VFDs)

Variable frequency drives (VFDs) have revolutionized how asynchronous motors are controlled and optimized for energy efficiency. Unlike traditional fixed-speed operation, VFDs adjust the frequency and voltage supplied to the motor, enabling precise speed and torque control.

Key energy-saving principles of VFDs include:

Matching Speed to Load Demand: Many industrial processes, such as pumping and ventilation, do not require constant motor speed. VFDs reduce motor speed when full load is unnecessary, cutting power consumption dramatically.

Reducing Inrush Current and Mechanical Stress: By ramping up motor speed gradually during startup, VFDs avoid the high inrush currents typical of direct-on-line starts, improving energy usage and reducing wear.

Minimizing Reactive Power Consumption: VFDs improve the power factor of motor systems, reducing reactive power draw and associated utility costs.

Studies show that integrating VFDs with asynchronous motors can yield energy savings of 20% to 50% depending on the application and operating profile, making them a critical tool in modern industrial energy management.

Soft-Start Technologies to Reduce Starting Impact

Starting an asynchronous motor directly on line often causes a sudden surge in current—up to 6-8 times the motor’s rated current—and creates mechanical shocks in connected equipment. This not only wastes energy but can also shorten equipment lifespan and increase maintenance needs.

Soft-start technologies, which gradually ramp up voltage to the motor during startup, address these issues effectively. Soft starters reduce the initial inrush current and torque spikes by controlling voltage applied to the stator, offering:

Lower Electrical Stress: Reducing demand peaks on the power supply network and minimizing energy waste during starts.

Reduced Mechanical Wear: Smoother acceleration limits stress on shafts, couplings, belts, and gearboxes.

Improved Process Control: More controlled startup sequences reduce downtime and prevent product damage in sensitive manufacturing processes.

Soft starters are especially beneficial for large asynchronous motors in pumps, fans, and compressors where frequent start-stop cycles occur.

Operational Management and Its Impact on Energy Efficiency

Optimizing motor operation through effective management practices plays a crucial role in realizing energy savings. Key operational strategies include:

Load Matching and Scheduling:Ensuring asynchronous motors operate only when necessary and close to their rated load capacity prevents energy waste caused by inefficient partial-load conditions. Proper scheduling of motor use optimizes energy consumption, reduces wear, and prolongs motor lifespan by avoiding unnecessary running time.

Regular Maintenance: Periodic inspection and servicing of asynchronous motors—including checking windings, bearings, and cooling systems—are essential to maintain peak efficiency. Timely maintenance prevents performance degradation caused by dirt buildup, lubrication loss, or component wear, ensuring consistent motor operation and energy savings.

Monitoring and Diagnostics: Implementing motor monitoring systems helps detect anomalies early, such as overheating, vibration, or power quality issues that reduce efficiency.

Training and Awareness: Educating operators and maintenance personnel on energy-efficient motor operation encourages best practices and timely interventions.

Effective operational management complements technological improvements, ensuring that investments in high-efficiency motors and controls translate into tangible energy savings.

Investment Return Analysis for Energy-Efficient Retrofits

Upgrading existing asynchronous motors and control systems involves upfront investment, but the long-term benefits often justify the cost through reduced energy bills and lower maintenance expenses. When evaluating retrofit projects, consider:

Energy Cost Savings: Calculate expected reductions in electricity consumption by comparing baseline energy use with projected savings from high-efficiency motor upgrades and VFD installations. These savings translate into significant long-term cost reductions and improved sustainability performance for industrial operations.

Maintenance Cost Reduction:Consider the extended motor lifespan and decreased frequency of repairs resulting from softer motor starts and improved operating conditions. Lower maintenance needs reduce labor and parts expenses, contributing to a more cost-effective and reliable motor system overall.

Downtime Avoidance: Evaluate the financial benefits of enhanced motor reliability, which leads to fewer unexpected failures and production interruptions. Minimizing downtime safeguards operational continuity and protects revenue streams in critical industrial processes.

Incentives and Rebates:Many governments and utility companies offer financial incentives, rebates, or tax credits to encourage investment in energy-efficient motors and controls. Leveraging these programs can significantly improve the return on investment and shorten payback periods for retrofit projects.

Typical payback periods for asynchronous motor energy-saving retrofits range from 1 to 3 years, with internal rates of return exceeding many traditional capital projects. Detailed feasibility studies help tailor the business case to specific industrial contexts.

Conclusion

In the pursuit of industrial energy efficiency, asynchronous motors present both challenges and opportunities. By combining high-efficiency motor designs, advanced control technologies like VFDs and soft starters, and disciplined operational management, industries can achieve significant reductions in energy consumption and operating costs.

For companies seeking to implement effective energy-saving solutions with asynchronous motors, Laeg Electric Technologies offers comprehensive expertise and cutting-edge products. Their portfolio includes high-efficiency motors, sophisticated drive controls, and turnkey retrofit solutions tailored to diverse industrial environments.

Discover how Laeg Electric Technologies can help your facility enhance motor system efficiency, lower carbon footprints, and achieve sustainable industrial automation goals. Visit their website or contact their specialists to explore customized solutions that fit your unique operational needs.